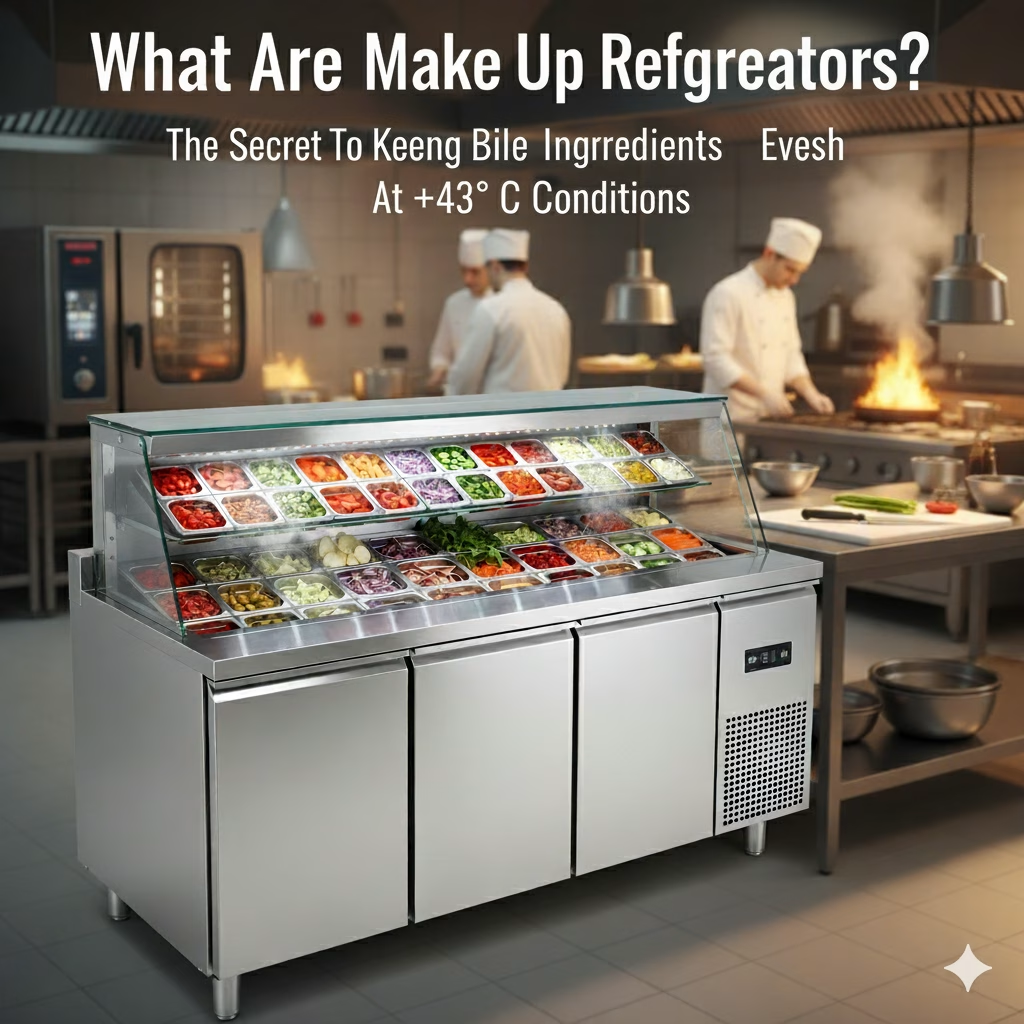

Commercial kitchens are often battlegrounds of continuously high temperatures and intense workflows. One of the most critical priorities for chefs and cooks is keeping ingredients readily accessible and at the ideal temperature during food preparation. The answer to this challenge lies with Make Up Refrigerators. These devices are far more than just a simple cooler; they are professional workstations that ergonomically display ingredients for immediate prep while guaranteeing stable temperatures from −2∘C to +8∘C. Especially near hot ovens or during peak summer days, ambient temperatures can exceed +40∘C. So, how do these industrial heroes manage to maintain the freshness and food safety of ingredients inside, even under extreme conditions up to +43∘C? The secret is hidden in the integration of design and technology. In this guide, we will examine What Make Up Refrigerators Are, why they are essential for kitchen efficiency, and uncover the three major secrets that keep your food flawless even in demanding +43∘C conditions.

What Are Make Up Refrigerators? Quick Prep and Commercial Definition

The role of a Make Up Refrigerator in commercial kitchens is akin to a “quick preparation center.” These units allow chefs and kitchen staff to keep fresh ingredients (such as chopped vegetables, cheeses, sauces, etc.) readily available and held at food safety standards while preparing items like sandwiches, pizzas, salads, appetizers, or desserts. Going beyond a standard under-counter refrigerator, these appliances feature special Gastronorm (GN) pan sections on the top, allowing ingredients to be displayed in an accessible, open showcase, while the drawers or lower compartments provide high-volume reserve storage.

The Key Differences Separating the Make Up Cooler from a Standard Under-Counter Refrigerator are very clear. Standard under-counter fridges usually serve only for storage, whereas Make Up models are designed as an active prep station. The GN pan area on the top allows ingredients for immediate use to be quickly selected and retrieved. Furthermore, because this top section works integrated with the cooling system below, it maintains the temperature of sensitive ingredients even with constant door usage. This creates a critical difference in efficiency and hygiene, particularly in fast-service restaurants or pizzerias.

The secret to efficiency is in GN Capacity and Speed of Access to Products. These refrigerators are designed to accommodate standard Gastronorm pans, such as GN 1/4 or GN 1/3. This allows staff to use standard-sized preparation trays and containers, avoiding clutter. The greatest benefit of a Make Up Refrigerator is that it prevents staff from constantly traveling back and forth to the main refrigerator. Since all ingredients are consolidated directly behind or below the preparation counter, workflow speed increases, and movement within the kitchen is minimized.

All this practicality is vital for Food Safety and Industrial Workflow. The primary goal of Make Up refrigerators is to ensure ingredients are kept out of the “danger zone” (the temperature range between 4∘C and 60∘C where bacteria proliferate). Thanks to the stable temperature control between −2∘C and +8∘C, sensitive ingredients (like meat, fish, or dairy products) are safely stored. This appliance is not just an efficiency tool; it is a fundamental part of your establishment’s food safety protocol.

Secret 1: The Guarantee of Flawless Cooling Even in +43∘C Ambient Conditions

The first and biggest secret to why a Make Up Refrigerator is far more valuable than a standard cooler is its incredible resilience to working conditions. These appliances, situated at the heart of industrial kitchens, must deliver unyielding cooling performance under the most challenging temperature circumstances.

The foundation of this performance lies in the Importance of Tropical Operating Capability. Many commercial refrigerators begin to struggle, their compressors run non-stop, and internal temperatures are difficult to maintain when the ambient temperature exceeds 30∘C. However, Make Up Refrigerators, which are positioned near pizza ovens, grills, and ranges, are expected to operate continuously and efficiently in high ambient temperatures reaching up to +43∘C and 65% humidity. This capability is achieved not only with a powerful compressor but also with specially designed cooling cycles and heat dissipation systems.

Despite these harsh conditions, the machine’s offered Temperature Range: Reliability from −2∘C to +8∘C is critical for food safety. The lower limit of −2∘C is ideal for lightly chilling and preserving the freshness of sensitive proteins (meat, fish), while the upper limit of +8∘C is the safe zone boundary for vegetables and other preparation ingredients. Maintaining temperature stability within this narrow and precise range prevents bacterial proliferation and keeps ingredients from losing flavor. This stability is the indispensable assurance provided by Make Up Refrigerators, especially when the external air temperature rises.

The third essential element ensuring this flawless performance is the Role of High-Density Insulation. The machine’s superior performance is not just because of a powerful cooling system; its walls and doors are lined with high-density, environmentally friendly (Zero ODP) polyurethane insulation, preventing external heat from penetrating the interior. For example, high-density insulation (e.g., 42 kg/m3) acts as a thermal barrier. This insulation ensures the compressor runs less, consumes less energy, and keeps the internal temperature significantly more stable, extending the appliance’s lifespan.

Secret 2: Energy Efficiency with Patented Technologies (Icecool)

When dealing with a piece of commercial equipment that runs 24/7, energy consumption is the largest long-term cost. The second secret of Make Up Refrigerators is the patented, intelligent technologies that allow them to deliver high performance while consuming minimal energy.

At the heart of this efficiency is the “Icecool” Patented Cooling System and Savings Potential. Standard cooling systems often use energy inefficiently, while patented systems like Icecool aim to reach the same degree of coldness with fewer compressor runs by optimizing the cooling cycle. This means less strain on the machine, quieter operation, and reduced energy consumption. The low kW consumption values specified by the manufacturer (e.g., 0.501 kW) significantly lower the electricity bill, allowing the appliance to amortize its cost more quickly.

Another smart technology contributing to efficiency is the Waste Heat Recovery Condensate Vaporizer System. When a Make Up Refrigerator‘s compressor runs, it generates heat that normally dissipates into the kitchen, forcing the kitchen’s air conditioning to work harder. The recovery system captures this waste heat energy and uses it to evaporate the condensate water from the refrigerator. This results in twofold energy savings: 1) The need for extra electricity to evaporate the condensate water is eliminated. 2) The load on the kitchen’s air conditioning is reduced as less heat is released into the environment.

The third major efficiency secret is the Hot Gas Defrost System and Effective De-icing. Frost buildup is a problem that reduces the efficiency of any cooler. The hot gas defrost system quickly eliminates frost by routing hot gas from the compressor to the evaporator plates for a short period. This is much more effective and faster than systems using electric heaters. The shorter defrost cycle allows the machine to return to cooling mode faster, preventing the disruption of the delicate temperature balance between −2∘C and +8∘C. Thus, Make Up Refrigerators are both efficient and uncompromising in food safety.

Secret 3: Professional Standards in Design and Hygiene

The third major secret of a Make Up Refrigerator is that it is designed to withstand intense daily use, not just for its motor power and insulation. In these appliances, design is not an aesthetic luxury but a fundamental necessity that ensures hygiene and efficiency.

The basis of hygiene is the provision of Stainless Steel (430 Grade) and Hygienic Surfaces. In a busy kitchen environment, an appliance subjected to constant contact, impact, and cleaning chemicals must be durable. Using 430 or higher-grade stainless steel not only ensures the device looks professional but also offers an easily cleanable, non-bacterial, and highly rust-resistant surface against humid conditions. This is a critical standard for food safety and hygiene inspections.

The second vital design secret is the Contribution of the 4-Door Design to Speed and Hygiene. Having four separate doors instead of one large one means staff only needs to open the section they require. What benefit does this bring? 1) Speed: Staff accesses the desired product faster. 2) Hygiene: Cold air loss is reduced with each door opening, keeping the overall internal temperature more stable and minimizing compressor strain. 3) Efficiency: Organizing different product categories behind separate doors prevents confusion.

Finally, Ergonomics and Marine Version Compatibility broaden the refrigerator’s utility. High-legged models allow for easy cleaning of the kitchen floor, while ergonomically designed door handles ensure staff can open and close the door effortlessly. Furthermore, the ability of these refrigerators to be produced in a marine version shows that the durability developed for land-based kitchens can be adapted to the turbulence, high humidity, and salty air of the sea. This means the appliance’s design is robust and reliable enough to withstand even the most extreme conditions.

Frequently Asked Questions

Which foods are ideal for a Make Up refrigerator? Make Up Refrigerators are ideal for all sensitive foods requiring rapid preparation. Primary uses include: Pizza/sandwich ingredients (cheese, cold cuts), salad bar items (chopped vegetables, greens), sauces, appetizer components, and dessert preparation materials. The −2∘C/+8∘C range provides ideal safety for proteins and dairy products.

How does GN 1/4 Capacity reflect in daily use? GN 1/4 capacity means the top display section can hold up to 15 small Gastronorm pans. This allows a chef preparing pizza or salad to keep all necessary components in one place—organized, cold, and without having to go to the main refrigerator. It dramatically accelerates the workflow.

How long does it take for these refrigerators to pay for themselves (amortize)? The amortization period depends on energy efficiency. Thanks to their high energy efficiency (low kW consumption), waste heat recovery, and ability to minimize food spoilage, Make Up Refrigerators can pay for themselves faster (typically within 2-4 years) compared to a standard model.

Why is operating in +43∘C conditions important? This indicates the refrigerator belongs to the tropical climate class. In industrial kitchens, ambient temperature easily exceeds +40∘C due to heat from ovens and ranges. This capability guarantees that the refrigerator continues to operate without disrupting internal temperature stability even during the busiest and hottest periods.

Is the digital control panel’s biggest advantage? The digital control panel allows you to set and monitor the temperature very precisely (±1∘C). Crucially, it provides an instant alert in cases like temperature deviation or a door being left open, preventing food loss.

Conclusion

Make Up Refrigerators are more than just cooling units in modern commercial kitchens; they are integrated prep stations that represent the peak of efficiency, hygiene, and food safety. Their performance, defying harsh conditions up to +43∘C, combined with patented energy systems like Icecool and ergonomic, GN-compatible designs, clearly sets them apart from standard models. Investing in a Make Up Refrigerator not only keeps your ingredients fresh but also increases your kitchen staff’s speed, reduces energy costs, and reinforces your business’s commitment to food safety standards.